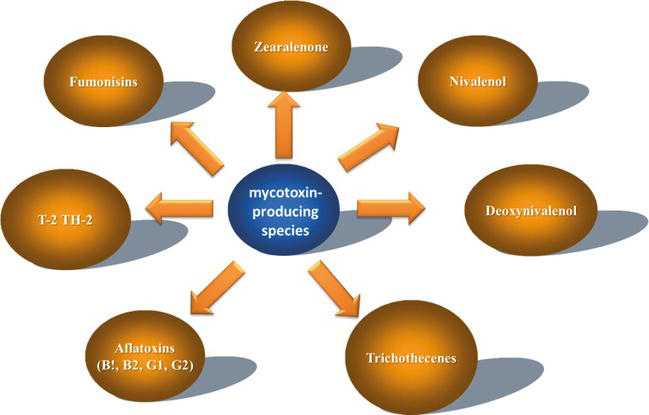

It is not the Mycotoxins that replicate themselves or form themselves, but the various fungi or Mycelium which produce them. It is the fungi that require the conducive environment to produce mycotoxins and various fungi produce peculiar, or multiple Mycotoxins that range from Aflatoxin to Fuminoxin, DON and Zearalenone, etc (Dr. Stephen Adejoro).

The conducive factors for these fungi must include appropriate substrate like corn, soy, groundnut, wheat, etc on which they require to grow. Water content in the substrate above the standard, or if the storage environment is damp, and if the temperature is increasing, all forms an ideal environment for fungi to grow and produce toxins.

It is interesting to note that the higher the heat in the environment where these fungi substrate is kept, the higher the Mycotoxin quantity that will be produced, and this is why more quantity of toxins are been produced as a result of climate change.

Climate change is characterized by all features that promote the secretion of toxins by feed or raw material contaminated fungi, as climate change produces flood drought, heat which is all conducive for the secretion and spread of toxins.

Quick check qualitative test for Mycotoxin at the farm gate is necessary and needed at farm gate level for fast decision by farmers, however quantitative test that can determine levels of toxin in raw materials and feed is a necessary tool for decision making on if toxin binders will be required to mitigate excess Mycotoxins in livestock feed.

The livestock industry foundation for Africa had since recognized a significant knowledge skill gap not only among farmers but also among many livestock professionals on Mycotoxin production identification and appropriate mitigation in the humid tropical climate. LIFA has concluded in many of her farmer’s training on Mycotoxin which is one of her initiative for advocacy that Mycotoxin is the most health-critical challenge of livestock that must be thoroughly understood and fully managed.

In 2020, Biomin analyzed 21,709 samples from 79 countries. The results showed that the most prevalent Mycotoxins globally in 2020 were the Fusarium Mycotoxins DON (65%) and FUM (64%), followed by ZEN (48%). According to Alexandro Marchioro, senior Mycotoxin expert at Biomin, reported that climate change is the main trigger influencing Mycotoxin prevalence around the globe. In a webinar presentation, he explained: Extreme weather conditions and events, like drought, desertification, and floods affect the life cycle of fungi, which influences Mycotoxin occurrence.

Incidentally, these two are large molecules toxin not commonly diagnosed or celebrated in Nigeria feed Industry, but which are most incriminated as major aestrogen for the repeated Vaccination failures we observed in the humid tropical climate of the South Sahara Africa. In LIFA we draw the attention of poultry farmers to this emergence and prevalence of these large molecules toxin in the region livestock feed raw materials.

We advise that emphasis should no more be focused on the Aflatoxin risk factors alone, however, we need to focus more on the implications of this large molecule toxin on poultry food security sustainability. Vaccination failures can reduce industry capacity by over 30% attributable to mortalities arising from Vaccination failures that are majorly caused by large molecules of the toxin.

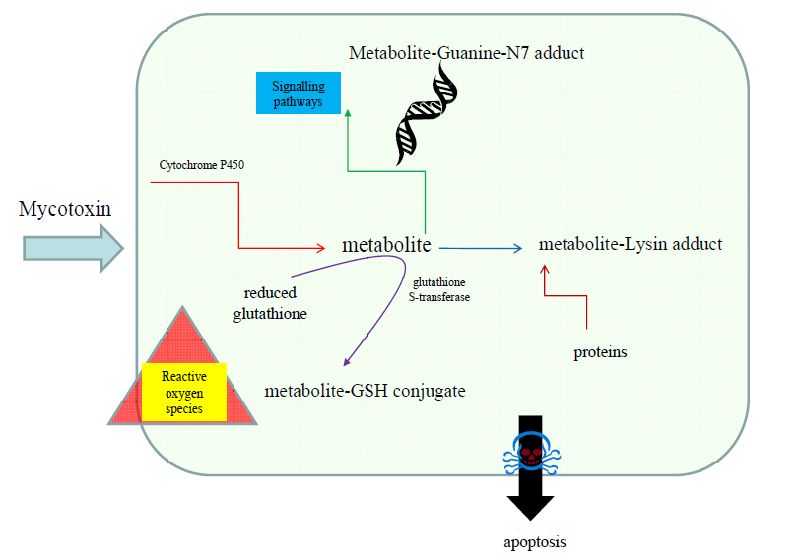

How do we best control these large molecule toxins? Large molecule toxins are larger in diameter than the interlayer spaces provided in most binders for binding common Mycotoxins like Aflatoxin and Ochratoxin. Recent technology like nanotechnology had simplified the mitigations of these large molecule toxins which also include Zearalenone an aestrogen structured like Mycotoxin that can attach to Zearalenone receptive sites, thereby sending wrong codes and signals in breeder reproduction.

Nanotoxin binders have wider interlayer spaces created by expanding interlayer spaces of Aluminum silicate layers with ulvans which are structured as interlayer algae pillars to increase most binders 0.25iu to 2.5micon which is about 10 times the original interlayer spaces of most binders in the market.

Mycotoxin affects all production and profitability indexes in poultry management, feeding, immunology, Vaccination successes, weight attainment, feed conversion, and the cost of medication in a poultry project, and we have come up with our slogan of “FAIL IN MYCOTOXIN MANAGEMENT AND FAIL IN ALL”.

We need to promote an ADVOCACY on the use of nanotechnology toxin binders in hot humid tropics of the South Sahara Africa where Mycotoxin are prolifically produced

For more information on managing your farm’s mycotoxin endemicity talk to technical experts at LIFA or contact lifango48@gmail.com